Link modular seal belt systems and gp disk seals are leading engineered solutions for sealing pipe through concrete walls.

Seal pvc pipe through concrete wall.

Sometimes they re not sealed at all.

Wall sleeves offer a cleaner installation for your engineered piping system.

If necessary fill the gap in layers of cement to build up the area slowly.

Under ground watertight high performance pipe sealing 36 72 psi.

These penetrations are one of the weakest links in the foundation walls when it comes to holding back groundwater and it s very common for them to leak water.

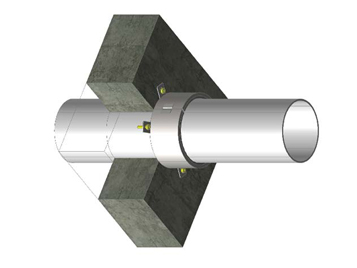

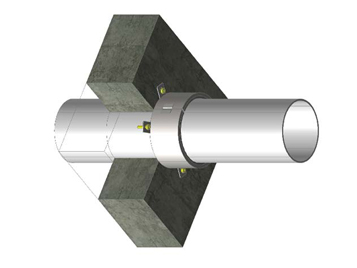

Wa ls gkd modular links seal pipe penetrations.

Standard weight steel or pvc pipe sleeve.

To make a sleeve a section of pipe two nominal trade sizes larger than the desired pipe is passed through the wall with 2 to 3 extending out either side of the wall.

Steel concrete cast iron hdpe pvc pipes and all pipe sizes.

Modular seal links create a positive seal both inwards and outwards to effective pressure sealing for pipes through concrete walls.

Building connection sealing systems from westatlantic.

Pour the mixed concrete around the pvc pipe using a large metal funnel or a spade.

Pack the concrete around the pvc pipe to prevent air gaps.

Up to 5 bar 72 psi pressure at temperatures from 40 f to 176 f 40 c to 80 c.

When pipes are run through the walls of your foundation they are typically sealed up with concrete hydraulic cement or caulk.

Pack the material in tightly and make sure the cement connects with both the pipe and surrounding wall.

Press hydraulic cement into the hole with a small trowel or putty knife.

The sleeve pipe may be sealed with mortar tar expansion foam or any other suitable means.

Creating a watertight annulus.